Izinduku eziqinile zeCarbide

![]() Isingeniso se-Solid Carbide Rods

Isingeniso se-Solid Carbide Rods

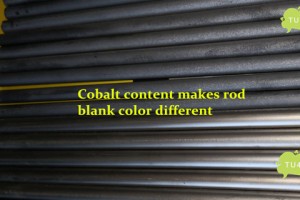

Induku eqinile ye-carbide yenziwa kakhulu nge-tungsten carbide, i-binder metal cobalt nezinye izithako ezisebenzayo ezifakiwe njengoba ifomula idinga, ngenhlanganisela yezinto, ukukhipha, i-pre-sinter, inqubo yokukhiqiza ukuguqulwa komumo bese isetshenziselwa ingcindezi ephansi. Ngezinhlamvu zobulukhuni obuphakeme, amandla aphakeme, amakhemikhali azinzile, i-coefficient yokwanda okuphansi, ukuqhutshwa kukagesi nokushisa, izinduku ze-sintered tungsten carbide zisetshenziswa kabanzi endaweni yokwenza izimboni, ngokwesibonelo, ukwenza i-micro drill embonini ye-PCB, ibha ye-electrode emphakathini we-optical imboni, i-drill, isitokisi sokubhola, ithiphu, i-pusher, gqoka izingxenye ezinemba ngokunemba, i-CNC reamer nama-blade anomgodi wokupholisa embonini yemishini.

Njengedepho ye-carbide, ifektri yesitshalo sensimbi iToonney ikhiqiza uhla olukhulu lwengxubevange ye-tungsten kufaka phakathi izinduku eziqinile, izinduku ezinembobo eqondile / evunguza yokupholisa, izinduku ezimise ngokuya ngemfuneko yekhasimende no-T obunjwe njll.

Izinduku eziqinile ze-tungsten carbide, akukho mibhobho yokupholisa ngaphakathi. Sinezinto eziyi-10 zefomula yokusetshenziswa okuvame kakhulu, isibonelo, izinduku ze-PCB micro drill, i-micro milling cutter, i-carbide saw blade, imishini yokwenza imishini ye-aluminium alloy, i-copper base alloy, i-steel base alloy kanye; wolfram carbide njll Silawula ngokuqinile ikhwalithi esinyathelweni ngasinye esidingekayo, singasho ukuthi ikhwalithi enhle ingenye yezinzuzo ezisenza sime kule mboni.

I-Wolfram carbide: I-Wolfram carbide iyinhlanganisela eyakhiwe yi-wolfram ne-carbide. I-crystal emnyama enezinhlangothi ezine-luster metallic, lapho ubulukhuni bufana nedayimane.I-Wolfram carbide ingumqhubi omuhle kagesi nokushisa, ayikwazi ukuncibilika emanzini, i-hydrochloric acid noma i-sulfuric acid, kepha inyibilika kalula kusixazululo esihlanganisiwe se-nitric acid kanye ne-hydrofluoric acid. I-wolfram carbide ehlanzekile ibuthakathaka, kepha uma ungeza i-titanium noma i-cobalt kanye ne-sintered, ubukhali buzoba bukhulu kakhulu. I-Wolfram carbide ibizwa nangokuthi i-tungsten carbide.

Insimbi ye-Tungsten / i-Tungsten metallic:I-Tungsten ibizwa nangokuthi i-wolfram, ifomu lensimbi enkulu ye-tungsten ekusetshenzisweni kwezimboni yi-tungsten carbide. Ifektri yensimbi yeToonney ikhiqize izinduku eziqinile ze-carbide iminyaka eminingi futhi ithola idumela elihle ekhaya nakwamanye amazwe.

Okufakiwe Yekuchumana: Isikhwama sepulasitiki, bese sivikelwe ngendwangu ye-foam, ekugcineni ebhokisini elingaphandle.

Izindaba Zezibonelo:Izinduku eziqinile ze-carbide ezingatholakala kuhlu lwethu oluvamile olujwayelekile, zinganikezwa njengamasampula mahhala. Ngezinduku eziqinile ze-carbide ezinamakhasimende akhethekile adingekayo, zizokhokhiswa. Vele, amakhasimende adinga ukukhokhela imali yokuthumela. Imvamisa, isikhathi sokuhola samasampuli sizoba phakathi kwezinsuku ezingu-7 zisebenza.

Ubuncane be-oda Ubuningi: Abukho ubuncane be-oda obuncane bezinduku eziqinile ze-carbide ye-oda lokuqala lokulingwa. Kepha ku-oda lesibili, inani eliphelele lezinduku eziqinile ze-carbide akufanele libe ngaphansi kuka-1000 USD.

Isikhathi sokuthumela: Izinsuku 7-15 zokusebenza

![]() Ukusika Amathuluzi Ebanga Lamathuluzi kanye Nokusetshenziswa

Ukusika Amathuluzi Ebanga Lamathuluzi kanye Nokusetshenziswa

| Ibanga | Co% | Okusanhlamvu Siz (μm) | Ubuningi (g / cm3) | Ukuqina (HRA) | I-TRS (N / mm2) |

| TU90 | 9.0 | 0.2 | 14.35 | 94.1 | 5200 |

| TF06 | 6.0 | 0.6 | 14.81 | 93.1 | 4000 |

| TU06 | 6.0 | 0.4 | 14.8 | 94.3 | 4600 |

| TU08 | 8.0 | 0.4 | 14.52 | 93.5 | 4800 |

| TU08S | 8.0 | 0.3 | 14.5 | 93.6 | 5000 |

| TU40 | 10.0 | 0.8 | 14.4 | 91.7 | 4600 |

| TU40F | 10.0 | 0.6 | 14.45 | 92.3 | 4600 |

| TU40S | 10.0 | 0.5 | 14.5 | 92.5 | 4800 |

| TU44 | 12.0 | 0.4 | 14.1 | 92.6 | 4800 |

| TU25 | 12.0 | 0.6 | 14.06 | 92.5 | 4200 |

| TU45 | 13.0 | 0.3 | 13.95 | 92.7 | 4800 |

| TU55 | 13.0 | 0.3 | 13.92 | 92.6 | 4800 |

![]() Isicelo Esinconyiwe

Isicelo Esinconyiwe

| Ibanga | Isicelo esinconyiwe |

| TU90 | Okokusika amathuluzi okusika okokusebenza okufingqiwe (HRC65-70), ukhuni oluqinile kanye nokusika okuphezulu kokupholisha. Kuhle kakhulu kubasiki abaqedile ukwenza imishini insimbi engu-316L |

| TF06 | Okokusika amathuluzi wokuchofoza i-aluminium magnesium alloy, i-graphite kanye ne-fiber eyinhlanganisela. |

| TU06 | Ukuze PCB micro-sokuprakthiza futhi ekupheleni isigayo machining super okusezingeni amahanisi izinsimbi. |

| TU08 | Ukuze PCB micro-sokuprakthiza, mini Milling umsiki. |

| TU08S | Okwebhodi le-micro PCB, amathuluzi okusika we-finis machining izinto eziqediwe (HRC60-65), i-316L insimbi engagqwali, ishidi eliphakeme lensimbi nensimbi yensimbi yensimbi. |

| TU40 | Ukuze ezivamile sokuprakthiza bit, ekupheleni isigayo futhi isibhakela die. |

| TU40F | Okwejwayelekile kokuprakthiza, ukuphela kwesigayo semishini ye-titanium alloy, insimbi engagqwali nensimbi yensimbi. |

| TU40S | Okokusika amathuluzi okusika insimbi engagqwali engu-316L, okokusebenza okungcono kwama-cuctter ajwayelekile ayindilinga. |

| TU44 | Okokusika amathuluzi wokuchofoza i-titanium alloy, ingxubevange engashisi ukushisa, insimbi engagqwali, insimbi emisiwe (HRC55 nangaphezulu), i-grey cast iron. |

| TU25 | Okokusika amathuluzi okusika insimbi ephathwa ukushisa (Ubulukhuni HRC45 nangaphezulu), insimbi yensimbi, insimbi engagqwali. |

| TU45 | Okokusika amathuluzi wokuchofoza i-titanium, ingxubevange emelana nokushisa, insimbi engagqwali, insimbi emisiwe (HRC60 nangaphezulu) |

| TU55 | Ibanga elinobunzima obuphezulu obomvu, okulungele ukusika amathuluzi wokuchofoza ingxubevange emelana nokushisa okuphezulu, insimbi ecinywayo (HRC60 nangaphezulu) ne-titanium alloy |

![]() Imininingwane ye-Solid Carbide Rods

Imininingwane ye-Solid Carbide Rods

| I-Dia. Ø mm |

Ukubekezelelana. (Mm) | Ubude (mm) | Ucingo. (Mm) | I-Dia.Ø (mm) | Ukubekezelelana. (Mm) | Ubude (mm) | Ucingo. (Mm) |

| 2.0 | + 0.30 / + 0.15 | 330 | 1.5 | 16.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 2.5 | + 0.30 / + 0.15 | 330 | 1.5 | 17.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 3.0 | + 0.50 / + 0.30 | 330 | 1.5 | 17.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 3.5 | + 0.50 / + 0.30 | 330 | 1.5 | 18.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 4.0 | + 0.50 / + 0.30 | 330 | 1.5 | 18.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 4.5 | + 0.50 / + 0.30 | 330 | 1.5 | 19.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 5.0 | + 0.50 / + 0.30 | 330 | 1.5 | 19.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 5.5 | + 0.50 / + 0.30 | 330 | 1.5 | 20.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 6.0 | + 0.50 / + 0.30 | 330 | 1.5 | 20.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 6.5 | + 0.50 / + 0.30 | 330 | 1.5 | 21.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 7.0 | + 0.50 / + 0.30 | 330 | 1.5 | 21.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 7.5 | + 0.50 / + 0.30 | 330 | 1.5 | 22.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 8.0 | + 0.50 / + 0.30 | 330 | 1.5 | 22.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 8.5 | + 0.50 / + 0.30 | 330 | 1.5 | 23.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 9.0 | + 0.60 / + 0.30 | 330 | 1.5 | 23.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 9.5 | + 0.60 / + 0.30 | 330 | 1.5 | 24.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 10.0 | + 0.60 / + 0.30 | 330 | 1.5 | 24.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 10.5 | + 0.60 / + 0.30 | 330 | 1.5 | 25.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 11.0 | + 0.60 / + 0.30 | 330 | 1.5 | 25.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 11.5 | + 0.60 / + 0.30 | 330 | 1.5 | 26.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 12.0 | + 0.60 / + 0.30 | 330 | 1.5 | 26.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 12.5 | + 0.60 / + 0.30 | 330 | 1.5 | 27.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 13.0 | + 0.60 / + 0.30 | 330 | 1.5 | 27.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 13.5 | + 0.60 / + 0.30 | 330 | 1.5 | 28.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 14.0 | + 0.70 / + 0.30 | 330 | 1.5 | 28.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 14.5 | + 0.70 / + 0.30 | 330 | 1.5 | 29.0 | + 0.8 / + 0.3 | 330 | 1.5 |